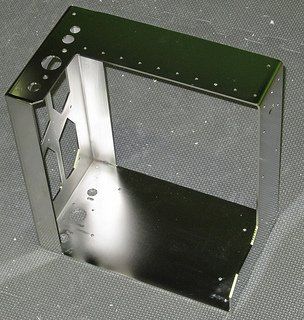

Like all Raytech Measuring Systems Inc tables, the Three Axis table starts as a welded steel frame. Unlike the Single Axis table, the Three Axis frame has the two inch thick steel plate welded directly to the frame. The frame then gets powder-coated with a textured finish which makes it durable enough for use on the shop floor. After powder coating, we send the frame out to have the top ground flat.

Once we get the frame back, it gets a good cleaning to remove all the grinding dust and fluid. Then we mount the linear bearings and encoders. We use a laser to align the bearings straight and parallel to each other for maximum accuracy. With that base built, we assemble the many parts necessary to build the bridge, calibrate the system with our NIST-traceable laser, and the machine is ready to be delivered.

We recommend the Three Axis table as one of our premier shopfloor metrology systems for appliances. Contact us today for more information.

Share On: