Like all Raytech Measuring Systems Inc tables, the Single Axis table starts as a welded steel frame. The frame then gets powder-coated with a textured finish which makes it durable enough for use on the shop floor.

Once the frame is finished, we then mount a ground steel plate to the top using a series of leveling bolts. These bolts let us adjust the top relative to the frame. By doing this, we get a flat working surface to support your material.

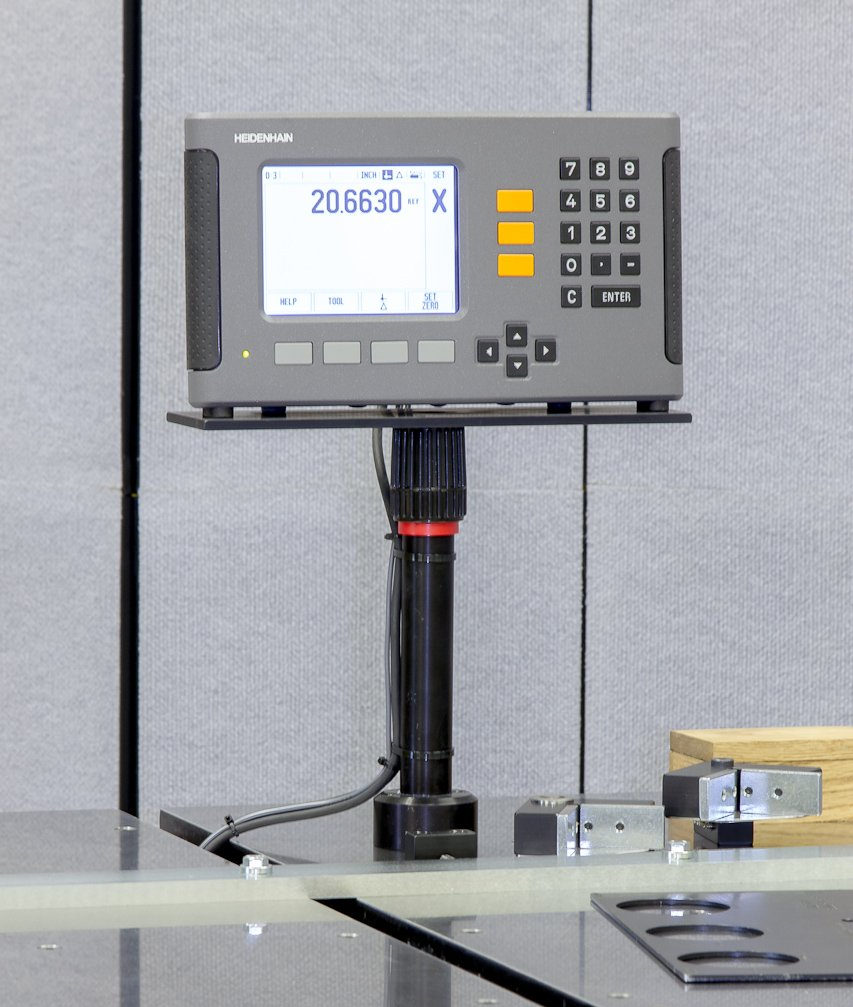

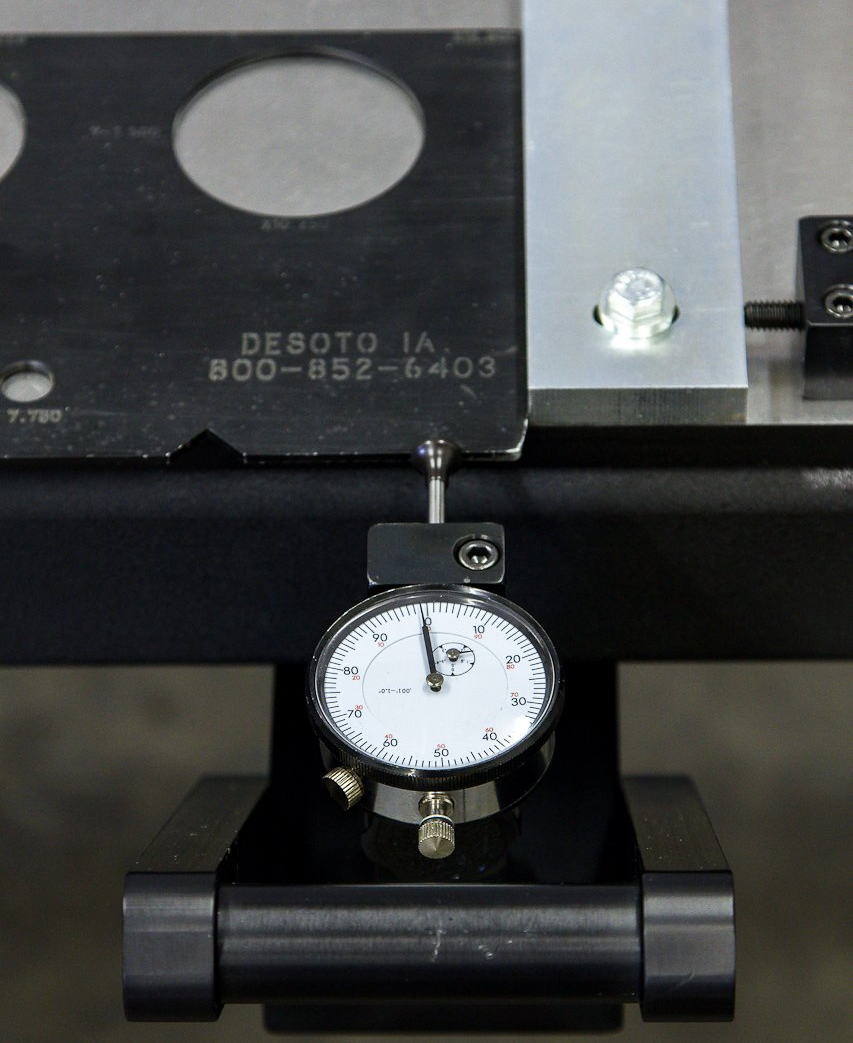

After the top is leveled, we mount the linear bearings and encoders, making sure they are straight and parallel for maximum accuracy. Assemble the parts, calibrate the table using a NIST-traceable laser system, and the machine is ready to be delivered.

Share On: